How Total Quality Management Can be Used for L&D

Reading Time:

Lead the pack with the latest in strategic L&D every month— straight to your inbox.

SubscribeCan a total quality management approach to organisational development make L&D a true business partner?

The whole total quality management schtick is to continually improve internal practices and performance, though generally speaking, that’s mainly applied in wider business practices. We’re here to say you can narrow your focus with it, to specifically use total quality management for L&D.

It’s not as cryptic to do as you may think. Read on to learn how this proven methodology can enable you to be a high-performing L&D department.

What is total quality management?

Total quality management (TQM) is a performance improvement process. It differs from industry processes like Six Sigma and DMAIC in that it focuses on the process of continually improving internal practices, performance and culture in order to improve performance in specific areas such as manufacturing and improving customer experience. On top of all that, TQM also ensures that employees are up to speed with training.

And this is where the link to learning and development starts. Caveat: TQM is not widely known or used within L&D. But just as L&D touches many areas of your organisation, total quality management has (or should have) its hooks in all L&D processes.

What is a TQM approach?

Before we get in depth, let’s really set the scene on what TQM is. The factors that affect total quality management can be either internal or external.

- Internally, it could be ways of work, capability gaps and knowledge systems.

- Externally, industry regulations will impact internal priorities and standards.

And since a picture tells a thousand words, it’s easier to show you how that looks broken down.

If you were to pull out the ‘TQM’ in the centre and replace it with ‘L&D’, you’ll begin to see why a proven methodology such as TQM is transferable.

Translating total quality management to L&D

The translation from TQM to L&D is nearer 1:1 than you may think. It just involves some critical thought when applying a quality management process to your workforce development endeavours, especially those ingrained in business performance.

Focus on the customer

It would be fair to say that learning leaders can have many customers. The number that comes to mind is clearly your workforce, but commonly L&D is also leaned on to support customer training, partner training and external credentialing, as examples. That support is generally two-fold.

- Acting as the subject matter expert to ensure any learning is the right solution to the customer problem

- Ensuring the right type of learning is offered, in order to be as impactful as possible.

If you ask Keith Meyerson, Director of Talent Management at POWDR, he sees himself as a business executive first, a talent and learning leader second (he literally says this here). Even if you’re not at the point where you’re mentally positioning yourself as such, then you’d at least know that the customer is always front and centre in a leadership meeting.

Employee involvement

Would it be L&D without employee involvement? You’d think not.

Then again, most will tell you that employee involvement is NPS and CSAT scores post-training. That’s entry level. Only one floor up is discussing with people leaders what training they require and transactionally taking the order. This only keeps you firmly planted in a cost centre seat.

For true business partnering and trust building, employee involvement starts with your CEO. And for true top to bottom employee involvement in your organisation, that means:

- Getting the business strategy documented on a page

- Understanding critical priorities and the capabilities needed to deliver them

- Mapping learning content and opportunities to capabilities.

When it comes to employee involvement, we want to push your thinking one step further. User-generated content has long been a thing in social media. At time of writing, TikTok and YouTube shorts have millions of users who are also creators. So why has L&D not yet piggy-backed onto this trend?

Anywhere between 60–90% of training requests are small courses for a niche audience. L&D can’t feasibly address all these individual needs. Employees also remain the best source of experiential knowledge within a business—which means that employee–generated content (and the systems and processes to support it) could very well be an untapped avenue for you.

Process centred

One could argue that TQM can’t teach us a whole lot about process in L&D, since most L&D professionals are already process centred.

The most commonly accepted process generally looks like:

- Assess

- Motivate

- Design

- Deliver

- Evaluate.

Where TQM comes in handy is that it keeps us grounded in proven processes. It can feel like there’s a new trend to capitalise on or exciting opportunity to show how innovative one can be in their role. TQM shows us that data and legacy can be the best way forward, especially when verifiable data is what your organisational powers-that-be want to see.

Integrated system

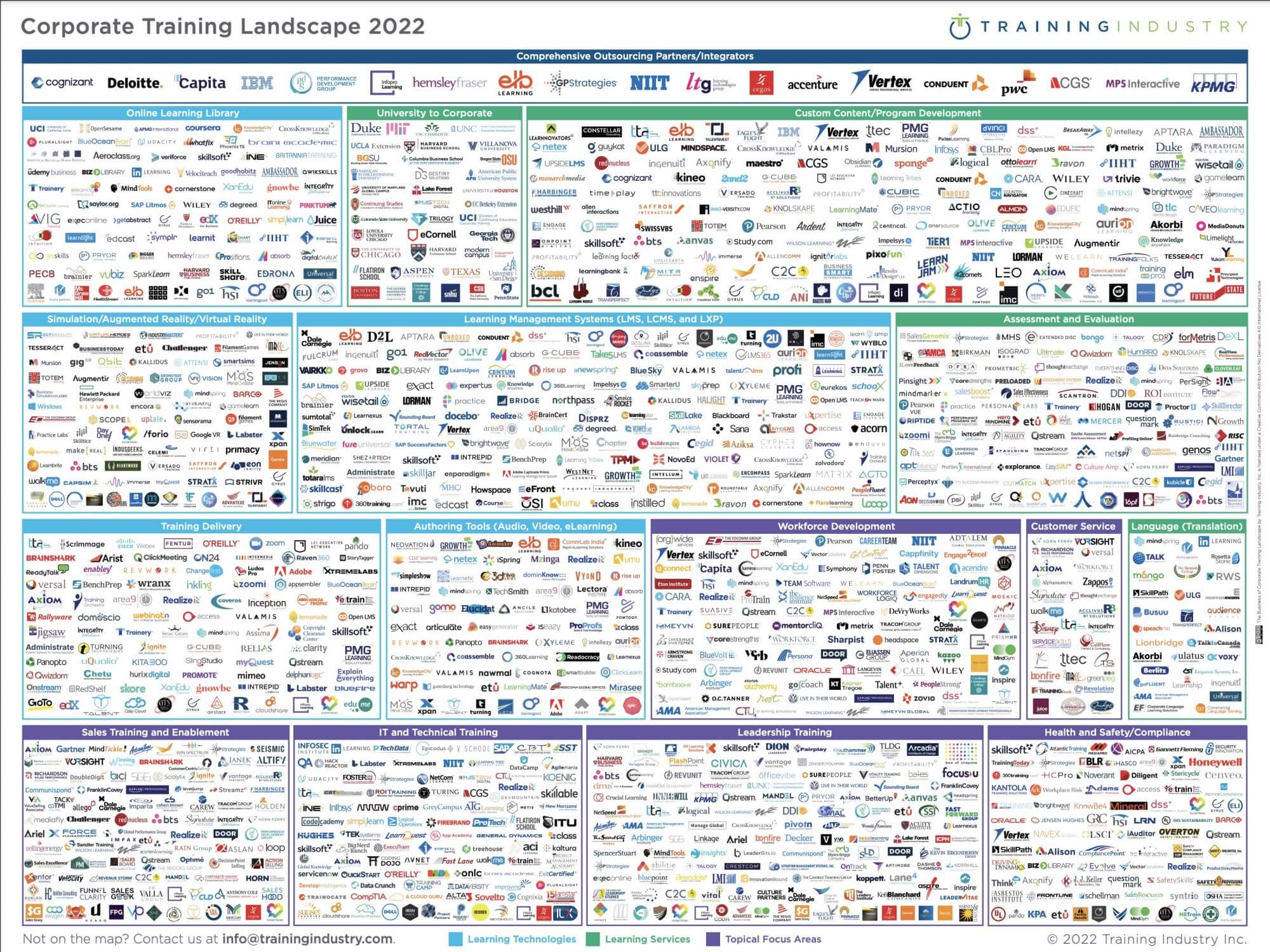

Just so we’re all on the same page, we’ll define “system” as the tools and technologies available to learning leaders today. And we’re not short of options:

That’s with xAPI, LTI, traditional API and, well, SFTP if needed. While we’re not sure of integration points, what we can assuredly take from TQM is that an integrated approach, with data flowing automatically and accurately, will deliver a superior performance of learning goals—and done right, business goals.

What’s the impact of not integrating your learning ecosystem?

Without integration, you start to create data and information silos. And the impact of that? It becomes super difficult to get a clear picture of performance. And if you head down the metaphorical hallway to speak with IT, they’ll also tell you it’s a no–no given it creates inefficiencies, increases risks of errors and in general slows down decision making and performance.

Strategic & systematic approach

If you’re like us, it can be easy to fall down a rabbit hold trying to build either strategy or systems in isolation. That’s what makes TQM crucial here: It offers a double-whammy strategic and systematic approach.

To again ensure we’re on the same page, we’re defining:

- Strategic as the big picture side of your L&D work. It’s linked to CEO strategic goals and mission–critical priorities.

- Systematic as the more logical and somewhat objective part of L&D work.

From the many conversations we’ve had, the highest–performing strategic approaches don’t have one exact blueprint to win (sorry, no silver bullet here). However, we have spotted patterns around collaboration between leaders’ organisational development, people capability, HR, L&D and business architecture. All or some of those generally work together to deliver on the business strategy via capability building.

From a systematic approach, we’ve observed the highest–performing method is to build a business capability map (which is a whole other story we investigated here).

Factual decision-making

Just as with processes, we give TQM kudos for keeping fact–based decision making at the fore.

We all know one’s opinions should not outweigh the known facts. But as is prevalent in business executive meetings across the land, he who shouts loudest commonly wins. Well, no more when it comes to L&D.

We’ll refer here to the Kirkpatrick Model for evaluation. However, we’ll first acknowledge that the model can have mixed reviews, or people may just not know about it. But we all need a stake in the ground to work from regarding decision making based on facts—together. And the Kirkpatrick model at least allows us to get to Level 4, business results.

When you’re working to improve business performance via L&D, what won’t cut it is superficial reporting metrics like butts on seats or average drop off rates. Go deep on empirical data in your training impact reports. And for the secret sauce (where training positively impacts a business outcome), act like a true business executive and name all the other correlating actions the business has taken to show that L&D played a part in the result.

Communication

It’s good to work with a team member who heads up organisational development here. Beyond what we already know of effective communication in L&D, TQM lifts the lid on change management and building the capacity of your workforce to change.

We’ve observed winning L&D team win on a capability-led strategy in this area. A capability being one set of skills, tools, processes and behaviours that, when combined with a host of capabilities in a framework, give you a strategic advantage. Communicating that by completing certain L&D initiatives because they are known to impact results gives learners context and, therefore, motivation to go on and not just complete learning but fully engage.

Continuous improvement

L&D never ends right? Whether it’s the surge of AI and machine learning, or the apparent explosion of AR and VR that’s coming our way. Continuous improvement is forever on our agenda.

There is nothing to say that’ll reinvent the wheel here (see: Process-centred to reread our thoughts on that), but this is a gentle reminder to embed consistent review and evaluation into your L&D processes in order to better understand learning efficacy. A performance learning management system (PLMS) can make this easier. A PLMS synchronises L&D activities to business performance, helping you to identify what learning works and what learning doesn’t, so you can tailor your TQM practices accordingly.

The impacts of TQM for L&D

Done right, strategic L&D has positive impacts on business outcomes. Along the same vein, TQM for L&D only serves to enable:

- Bigger ROI for less effort and cost

- Standardisation of quality improvement methods

- Efficacy of business-aligned L&D metrics

- Quick identification of process weaknesses or risks

- A culture of continuous effort and iteration

- Iteration of total quality management principles.

Key takeaways

Total quality management is a long-held tool in wider business practices, but incorporating it into L&D processes and strategy may seem somewhat like exploring a new world. We’re here to say it’s not as big a mental shift as you may think—rather, it’s a matter of thinking about the impacts of L&D.

The traditional way to implement total quality management involves a number of principles. Translating those principles to L&D means looking through the lens of L&D as a business partner.

- Customer focus: Position yourself as a business exec first, learning leader second.

- Employee involvement: Turn learning from an order-based transaction to employee-generated trove of content.

- Process centric: Don’t innovate for the sake of innovation.

- Integrated system: Combine and automate your people, learning and organisational data.

- Strategy and systems: Mapping capabilities to business architecture gives you a clearer view of priorities.

- Decision making: Root everything in tangible data and facts so everyone’s on the page.

- Communication: Context is king, and will change the tide of engagement when you provide relevant learning opportunities.

- Continual improvement: Review your methods, constantly.